Cds Tube Suppliers Supplier – Wholesale ASTM 1020 Quilted steel pipe – Wald

Cds Tube Suppliers Supplier – Wholesale ASTM 1020 Quilted steel pipe – Wald Detail:

Processing Technology

The quilted steel pipe is processed by rolling. Due to the residual compressive stress on the surface layer, it is helpful to close the small cracks on the surface and hinder the expansion of erosion. So as to improve the corrosion resistance of the surface and delay the generation or expansion of fatigue cracks, so as to improve the fatigue strength of quilted steel pipe. Through rolling forming, a cold work hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, improves the wear resistance of the inner wall of the quilted steel pipe, and avoids the burn caused by grinding. After rolling, the reduction of surface roughness can improve the matching properties.

Rolling is a kind of chip free processing, which uses the plastic deformation of metal at room temperature to flatten the micro unevenness of the workpiece surface, so as to change the surface structure, mechanical characteristics, shape and size. Therefore, this method can achieve the two purposes of finishing and strengthening at the same time, which can not be achieved by grinding.

No matter what processing method is used, fine uneven knife marks will always be left on the surface of parts, resulting in staggered peaks and valleys,

Principle of rolling processing: it is a kind of pressure finishing processing, which uses the cold plastic characteristics of metal at room temperature and applies certain pressure on the workpiece surface with rolling tools to make the metal on the workpiece surface produce plastic flow and fill it into the original residual low concave trough, so as to reduce the roughness value of the workpiece surface. Due to the plastic deformation of the rolled surface metal, the surface structure is cold hardened and the grain becomes fine, forming a dense fibrous shape, forming a residual stress layer, and improving the hardness and strength, so as to improve the wear resistance, corrosion resistance and compatibility of the workpiece surface. Rolling is a plastic machining method without cutting.

Processing Advantages

1. Improve the surface roughness, and the roughness can basically reach RA ≤ 0.08 & micro; M or so.

2. Corrected roundness, ovality can be ≤ 0.01mm.

3. Improve the surface hardness, eliminate the stress deformation, and increase the hardness by HV ≥ 4.

4. There is residual stress layer after processing, and the fatigue strength is increased by 30%.

5. Improve the matching quality, reduce wear and prolong the service life of parts, but the processing cost of parts is reduced.

Difference

Difference between quilted steel pipe and seamless steel pipe

1. The main feature of seamless steel pipe is no welding joint, which can withstand large pressure. The product can be very rough as cast or cold drawn parts.

2. Quilted steel pipe is a product appeared in recent years, which mainly has strict tolerance and roughness for the dimensions of inner hole and outer wall.

Characteristics of quilted steel pipe

1. Smaller outer diameter.

2. High precision and can be produced in small batch

3. Cold drawn products have high precision and good surface quality.

4. The cross area of steel pipe is more complex.

5. The steel pipe has superior performance and dense metal.

Differences After Hot Rolling Quilted Steel Pipe

The hot-rolled precision steel pipe uses the continuous casting round tube slab or blooming slab as the raw material, which is heated by the stepping heating furnace and descaled by high-pressure water before entering the roughing mill. The roughing material enters the finishing mill after cutting, tailing and then entering the finishing mill for computer {controlled rolling. After the final rolling, it is rolled into a straight hair coil through laminar cooling and coiler. The head and tail of straight hair curl are often tongue shaped and fishtail shaped, with poor accuracy of thickness and width, and there are often defects such as wave shape, hem, tower shape and so on. The coil weight is heavy and the inner diameter of the steel coil is 760mm. After the straight hair coil is processed by head cutting, tail cutting, edge cutting, multi pass straightening, leveling and other finishing lines, it is then cut or rewound to become hot-rolled steel plate, flat hot-rolled steel coil, longitudinal cutting belt and other products. If the hot-rolled finishing coil is pickled to remove the oxide scale and coated with oil, it will become a hot-rolled pickled coil.

Common Materials

10# 0.07~0.13 0.17~0.37 0.35~0.65 ≤0.035 ≤0.035

20# 0.17~0.23 0.17~0.37 0.35~0.65 ≤0.035 ≤0.035

35# 0.32~0.39 0.17~0.37 0.35~0.65 ≤0.035 ≤0.035

45# 0.42~0.50 0.17~0.37 0.50~0.80 ≤0.035 ≤0.035

40cr 0.37~0.44 0.17~0.37 0.50~0.80 ≤0.035 ≤0.035 0.08~1.10

25Mn 0.22~0.2 0.17~0.37 0.70~1.00 ≤0.035 ≤0.035 ≤0.25

37Mn5 0.30~0.39 0.15~0.30 1.20~1.50 ≤0.015 ≤0.020

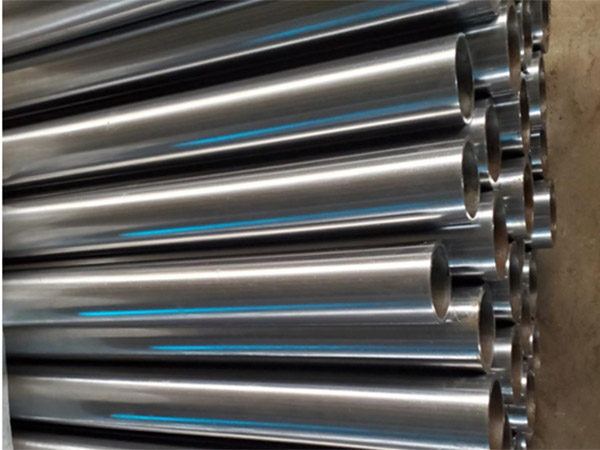

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Cds Tube Suppliers Supplier – Wholesale ASTM 1020 Quilted steel pipe – Wald, The product will supply to all over the world, such as: Israel, Cape Town, Mexico, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.