Profile

Processing Technology

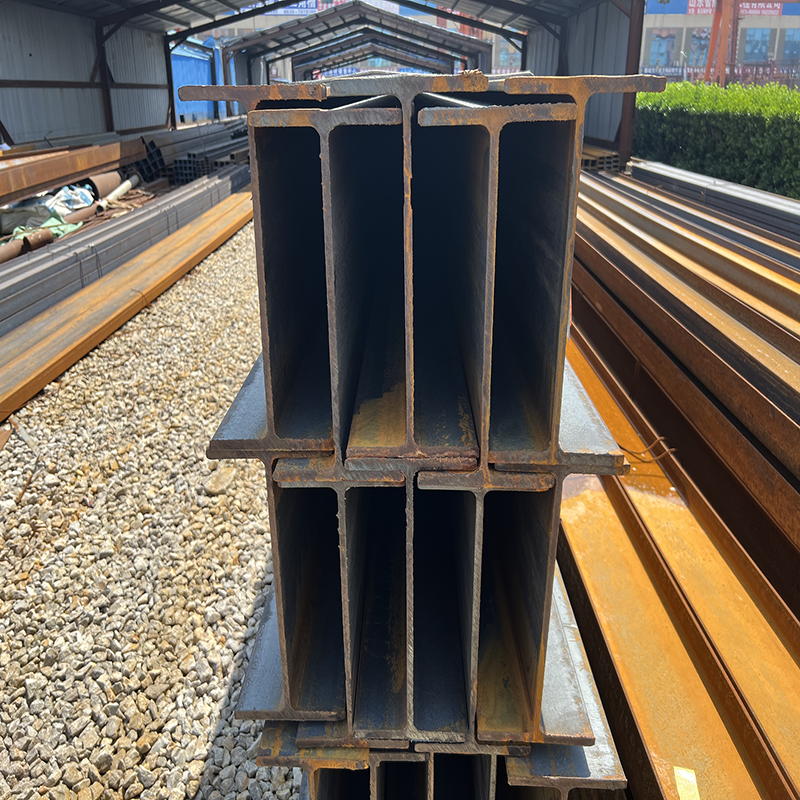

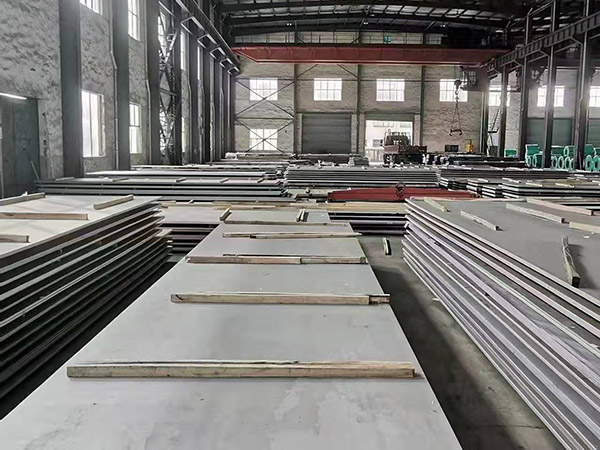

Profile is an object with certain geometry made of iron or steel and materials with certain strength and toughness through rolling, extrusion, casting and other processes. This kind of material has certain appearance size, certain cross-section shape and certain mechanical and physical properties. Profiles can be used alone or further processed into other manufactured products, which are commonly used in building structure, manufacturing and installation. The mechanical engineer can select the specific shape, material, heat treatment state, mechanical properties and other parameters of the profile according to the design requirements, then divide the profile according to the specific size and shape requirements, and then further process or heat treatment to meet the accuracy requirements of the design. The material, specification and size of profile can refer to the corresponding national standards.

Profile production has the following characteristics:

(1) There are many varieties and specifications. It has reached more than 10000 kinds. In production, except for a few special rolling mills producing special products, the vast majority of profile rolling mills are producing multiple varieties and specifications.

(2) Large difference in section shape. In profile products, except that the section shapes of square, round and flat steel are simple and have little difference, most complex section profiles (such as I-beam, H-beam, Z-beam, channel steel, rail, etc.) not only have complex section shapes, but also differ greatly from each other. The pass design and rolling production of these products have their particularity; The complexity of section shape makes the deformation of metal parts, section temperature distribution and roll wear uneven in the rolling process. Therefore, it is difficult to accurately calculate and control the size of rolled piece, and the adjustment of rolling mill and the installation of guide device are also complex; In addition, the single variety or specification of complex section profile is usually small in batch. The above factors make it difficult to develop the continuous rolling technology of complex section profiles.

(3) There are many mill structures and mill layout forms. In terms of structural form, there are two high mill, three high mill, four high universal pass mill, multi high pass mill, Y-shaped mill, 45 ° mill and cantilever mill. In terms of rolling mill layout, there are horizontal rolling mill, in-line rolling mill, checkerboard rolling mill, semi continuous rolling mill and continuous rolling mill.