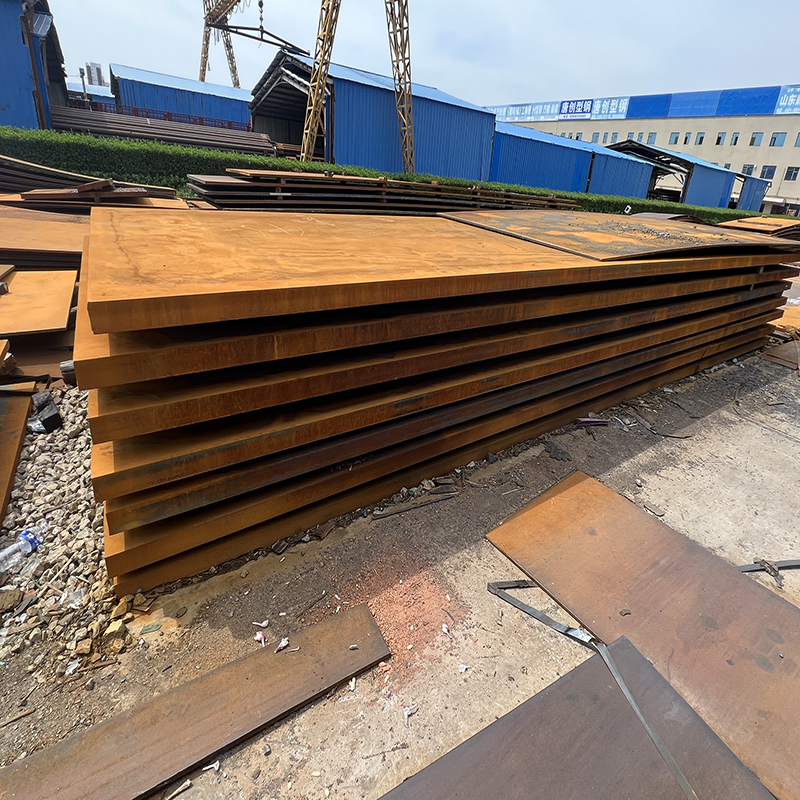

Wear resistant steel plate

Processing Technology

Wear resistant steel plate is composed of low-carbon steel plate and alloy wear-resistant layer. The alloy wear-resistant layer is generally 1 / 3 ~ 1 / 2 of the total thickness. During operation, the matrix provides comprehensive properties such as strength, toughness and plasticity to resist external forces, and the alloy wear-resistant layer provides wear-resistant properties that meet the requirements of specified working conditions.

The wear-resistant steel plate is metallurgically bonded between the alloy wear-resistant layer and the substrate. Through special equipment and automatic welding process, the high hardness self protective alloy welding wire is evenly welded on the substrate. The number of composite layers is one to two or even multiple layers. During the composite process, uniform transverse cracks appear due to different alloy shrinkage ratio, which is the remarkable feature of wear-resistant steel plate.

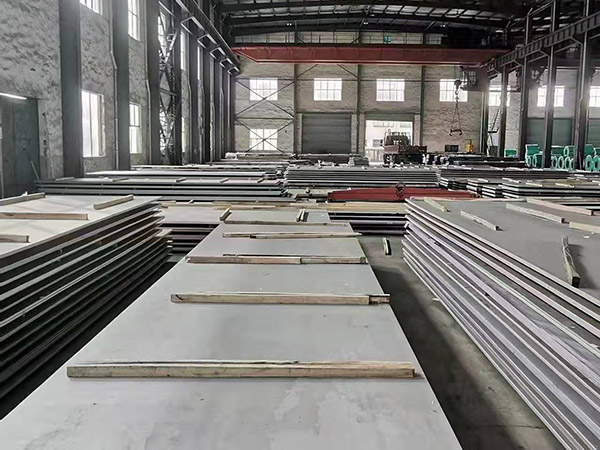

The alloy wear-resistant layer is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are also added. The carbides in the metallographic structure are distributed in fiber shape, and the fiber direction is perpendicular to the surface. The micro hardness of carbide can reach above hv1700-2000 and the surface hardness can reach HRC58-62. Alloy carbides have strong stability at high temperature, maintain high hardness, and have good oxidation resistance. They can be used normally within 500 ℃.

The wear-resistant layer takes the form of narrow channel (2.5-3.5mm), wide channel (8-12mm), curve (s, w), etc; It is mainly composed of chromium alloy and other alloy components such as manganese, molybdenum, niobium, nickel and boron. The carbides in the metallographic structure are distributed in fiber shape, and the fiber direction is perpendicular to the surface. The carbide content is 40-60%, the microhardness can reach more than hv1700, and the surface hardness can reach HRC58-62.

Scope of application

Wear resistant steel plate has high wear resistance and good impact performance. It can be cut, bent and welded. It can be connected with other structures by welding, plug welding and bolt connection. It is time-saving and convenient in the process of maintenance. It is widely used in metallurgy, coal, cement, electric power, glass, mining, building materials, brick and tile and other industries. Compared with other materials, it has high cost performance, It has been favored by more and more industries and manufacturers.